Types of Router Bits for Shaker Style Cabinet Doors

Shaker style cabinet doors, known for their clean lines and simple elegance, rely heavily on precise router bit selection for achieving their characteristic profiles. The choice of bit directly impacts the final aesthetic and the ease of the woodworking process. Understanding the different types available, their materials, and their applications is crucial for successful Shaker door construction.

Router Bit Types for Shaker Door Profiles

Several router bit types are commonly employed to create the various elements of Shaker doors. These include bits for creating raised panels, flat panels, and beaded insets, each requiring specific profiles and sizes. The selection depends on the overall design and the desired level of detail.

- Raised Panel Bits: These bits create the recessed area around a raised panel. Common profiles include ogee, cove, and Roman ogee. Sizes vary depending on the desired panel depth and overall door size, typically ranging from 1/4″ to 1/2″ in cutting diameter. A larger diameter creates a more substantial raised panel effect. The bit’s bearing diameter is crucial for consistent depth and edge profile.

- Straight Bits: Used for creating clean, crisp edges and for cutting the rabbets needed for the door’s frame. Straight bits come in various diameters, with those ranging from 1/4″ to 1/2″ being commonly used for Shaker door construction. The shank diameter (typically 1/4″ or 1/2″) must match the router’s collet.

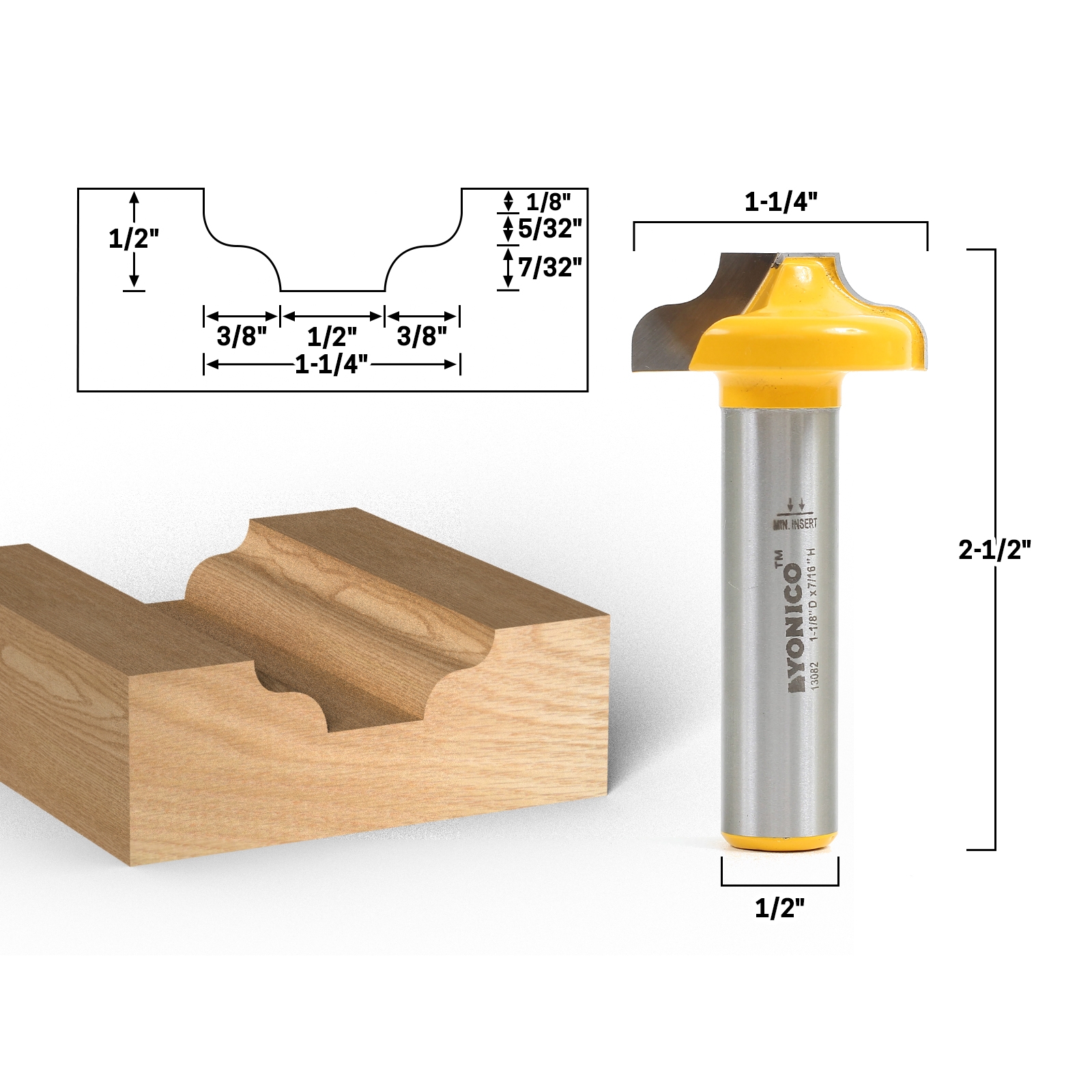

- Beading Bits: These bits create a decorative bead along the edges of the door’s frame or panel. Sizes vary widely depending on the desired bead size, ranging from very small, delicate beads to larger, more pronounced ones. The bit’s profile determines the shape of the bead (e.g., round, cove, ogee).

- Flush Trim Bits: These bits are used to create a clean, flush surface between the door frame and the raised panel. They have a bearing that rides along the edge of the panel, ensuring a consistent and even cut. The bit diameter is typically slightly larger than the panel thickness.

Router Bit Material Comparison: Carbide vs. High-Speed Steel

The material of the router bit significantly influences its performance, longevity, and cost. Carbide and high-speed steel (HSS) are the two most common materials.

- Carbide Router Bits: Carbide bits are significantly harder and more durable than HSS bits. They retain their sharpness much longer, resulting in cleaner cuts and less frequent sharpening. This makes them ideal for mass production or for working with hardwoods that are more challenging to cut. However, they are more expensive upfront.

- High-Speed Steel (HSS) Router Bits: HSS bits are less expensive than carbide bits, making them a more budget-friendly option for smaller projects or hobbyists. However, they require more frequent sharpening and are more prone to chipping or dulling, especially when working with hardwoods or abrasive materials. They are often preferred for softer woods where the increased sharpness of a freshly sharpened bit is valued.

For example, when creating a large number of Shaker doors for a kitchen renovation, carbide bits are a worthwhile investment due to their longevity. For a single, small project using softwood, an HSS bit might suffice.

Selecting the Appropriate Router Bit for Shaker Cabinet Doors

Choosing the right router bit involves careful consideration of several factors. The wood type significantly impacts the bit selection. Hardwoods require more durable bits, often carbide, while softer woods can be worked with HSS bits. The desired finish also plays a role; for a fine, smooth finish, sharp bits are crucial. Finally, the specific design dictates the profiles and sizes of the bits required. For instance, a simple Shaker door with a flat panel might only need straight bits and a flush trim bit, whereas a more elaborate design with raised panels and beaded edges will require a wider array of bits with specific profiles. Accurate measurements of the door components are essential to ensure the correct bit sizes are chosen to achieve the desired results.

Techniques for Using Router Bits on Shaker Doors: Router Bits For Shaker Style Cabinet Doors

Creating beautiful shaker-style cabinet doors with a router requires precision and careful technique. This section details the process, emphasizing safety and achieving consistently clean results. Mastering these techniques will elevate your woodworking projects from good to exceptional.

Raised Panel Shaker Door Creation

Constructing a raised panel shaker door using a router involves several precise steps. Accurate measurements and the proper use of jigs are crucial for achieving a professional finish. Failure to adhere to safety precautions can lead to injury or damage to the workpiece.

| Step | Tool | Action | Potential Problem |

|---|---|---|---|

| 1. Prepare the Door Frame | Table Saw, Jointer, Planer | Cut and square the stiles and rails to the desired dimensions. Ensure all surfaces are smooth and flat. | Inaccurate cuts leading to misaligned joints. Use a miter saw with a fence for accurate cuts. |

| 2. Assemble the Frame | Clamps, Wood Glue, Dowel Jig (Optional) | Glue and clamp the stiles and rails together, ensuring squareness. Dowels can provide additional strength. | Glue squeeze-out, misaligned joints. Use appropriate clamping pressure and check for squareness frequently. |

| 3. Cut the Panel Groove | Router, Straight Bit | Use a router and straight bit to create a groove in the inside edges of the frame to receive the panel. Use a router table or jig for consistent depth and accuracy. | Tear-out, inconsistent depth. Use a sharp bit, appropriate feed rate, and a sacrificial board under the workpiece. |

| 4. Create the Raised Panel | Router, Panel Raising Bit | Use a panel raising bit to create the raised panel profile on the chosen panel material. Use a jig for consistent results. | Tear-out, inconsistent profile. Use a sharp bit, slow feed rate, and clamp the workpiece securely. |

| 5. Fit and Glue the Panel | Clamps, Wood Glue | Fit the raised panel into the groove and glue it in place. Ensure the panel is flush with the frame. | Gaps between the panel and frame. Ensure the groove is the correct size and the panel fits snugly. |

| 6. Sand and Finish | Sander, Sandpaper, Finish | Sand the entire door smooth, paying attention to transitions between the frame and panel. Apply the desired finish. | Uneven finish, sanding marks. Use progressively finer grits of sandpaper and apply finish evenly. |

Achieving Clean and Precise Cuts

Several techniques contribute to clean, precise cuts when routing shaker details. Minimizing tear-out requires careful attention to bit selection, feed rate, and workpiece preparation. Using jigs dramatically improves consistency and reduces errors.

To minimize tear-out, always use sharp router bits. A dull bit will cause the wood fibers to tear instead of cleanly cutting them. Feed the router slowly and steadily, avoiding jerky movements. Using a sacrificial board underneath the workpiece can also help prevent tear-out on the bottom surface. Employing push blocks and feather boards offers added control and safety. For particularly delicate work, consider using a router table with a fence to provide more consistent results. Pre-drilling pilot holes for any dadoes or mortises significantly reduces the risk of tear-out and chipping. Properly clamping the workpiece to prevent movement is crucial for clean cuts. Finally, selecting the correct bit for the specific task is essential for achieving the desired profile and minimizing tear-out.

Workflow for Creating Matching Shaker Doors

Creating a set of matching shaker doors requires a systematic approach. Careful planning and the use of jigs are essential for ensuring consistency across all doors. Choosing the correct router bits is critical for achieving the desired aesthetic.

The workflow begins with precise measurements and the creation of templates for all components (rails, stiles, and panels). Next, cut the necessary pieces using the table saw and jointer, ensuring accurate dimensions and squareness. Using a jig for routing the panel grooves and raised panels will ensure consistent results across all doors. Assembly of the frames is followed by fitting and gluing the raised panels. Finally, sanding and finishing complete the process. Utilizing a jig for consistent panel sizing and groove routing greatly enhances efficiency and accuracy. Selecting bits appropriate for the chosen profile and material is also crucial for quality results. Consistent clamping pressure throughout the process will maintain squareness and prevent misalignment.

Shaker Style Door Design Variations and Router Bit Applications

Shaker style cabinet doors, known for their clean lines and simple elegance, offer a surprising degree of design flexibility achievable through careful selection and application of router bits. Variations in rail and stile profiles, panel designs, and edge treatments all contribute to the overall aesthetic, and each requires specific router bit choices for precise execution. Understanding these relationships allows for both replication of classic designs and the creation of unique, customized pieces.

Rail and Stile Profile Variations

The basic Shaker door features a flat rail and stile construction, but numerous variations exist. A simple raised panel door might utilize a straight bit to create a flush rail and stile, then a larger, raised panel bit to form the recessed panel. Alternatively, a cove bit can be used on the rails and stiles to create a subtle, curved profile, adding a touch of softness to the otherwise austere design. A Roman Ogee bit offers a more pronounced, elegant curve, while a chamfer bit can be used to create a simple bevel along the edges of the rails and stiles. The choice of bit dictates the overall visual character of the door—from minimalist to more ornate. For instance, a combination of a straight bit for the panel recess and a cove bit for the edges creates a visually interesting contrast.

Panel Design Options

The panel itself provides another avenue for customization. The classic Shaker flat panel can be easily created using a straight bit to rout the recess. However, more intricate designs are possible. A raised panel bit can create a raised panel with a variety of profiles, depending on the bit’s design. A recessed panel, slightly inset from the rail and stile, can be achieved with the same type of bit, using different depth settings. A beaded panel, with a decorative beading around the perimeter, requires a specific beading bit. Finally, a more complex panel design might involve combining multiple bits, such as using a cove bit to create a curved recess around a raised center panel. The possibilities are numerous and limited only by the woodworker’s skill and imagination.

Adapting Router Bit Techniques for Unique Profiles

Creating truly unique Shaker door profiles involves combining different router bits and techniques. For example, using a combination of a chamfer bit and a round-over bit on the rails and stiles can produce a distinctly different look. The chamfer softens the sharp edges, while the round-over adds a subtle curve. Another approach is to incorporate contrasting wood species in the rails and stiles, emphasizing the clean lines of the Shaker design. Precise routing with the correct bits is crucial to ensure clean, crisp transitions between the different wood elements. Using a template to guide the router is highly recommended for complex designs to ensure consistency and accuracy. A further level of customization involves creating custom profiles by modifying existing router bits or creating your own using specialized tooling. While requiring more advanced woodworking skills, this allows for entirely unique and personalized Shaker door designs.

Rewritten Article: Router Bits for Shaker Style Cabinet Doors

Introduction

Shaker-style cabinet doors are renowned for their clean lines and simple elegance. Achieving this aesthetic requires precise woodworking techniques, and router bits are essential tools for creating the characteristic features of these doors. This guide details the various router bits used and how to apply them effectively.

Choosing the Right Router Bits

Several types of router bits are crucial for constructing Shaker doors. Straight bits are used to create the recesses for the panels. Raised panel bits create the raised or recessed panel profiles. Ogee, cove, and Roman Ogee bits create curved profiles on the rails and stiles, offering design variations. Chamfer bits create angled edges, while round-over bits produce a smooth, rounded edge. The selection depends entirely on the desired door design.

Techniques for Using Router Bits

Accurate setup and execution are paramount. Always use a sharp bit, and ensure the router is securely clamped to a router table or appropriate jig. Using a template for consistent results, especially for complex profiles, is highly recommended. Multiple passes at shallower depths are preferred to avoid tear-out, particularly in harder wood species. Pay close attention to bit speed and feed rate for optimal results. Proper safety precautions, including the use of safety glasses and hearing protection, are always mandatory.

Creating Shaker Door Variations

The basic Shaker door can be significantly customized using different bit combinations and techniques. A flat panel door uses only a straight bit. A raised panel door utilizes a raised panel bit in conjunction with a straight bit. More complex profiles are achieved by combining various bits, such as a cove bit with a straight bit, or an ogee bit with a chamfer bit. The options are vast, allowing for highly individualized designs.